May 22, 2025

How to Use AI for International Agricultural Product Sourcing

Learn how to use AI to streamline international agricultural sourcing. Discover tools, strategies, and benefits for smarter, faster global procurement.

February 26, 2025

Ensuring the quality and safety of dried mango during international transit hinges on robust export packaging. Following specific guidelines protects the product from damage, spoilage, and contamination, maintaining its value and meeting regulatory requirements.

Proper packaging is paramount. It directly affects the shelf life, appearance, and overall consumer appeal of dried mango. Inadequate packaging can lead to moisture absorption, pest infestation, physical damage during shipping, and ultimately, financial losses. Furthermore, adherence to packaging standards builds trust with international buyers and facilitates smoother customs clearance.

Several aspects are critical when specifying packaging for dried mango Philippines exports:

The packaging material must be food-grade, durable, and capable of providing an effective barrier against moisture, oxygen, and light. Common choices include:

Polypropylene (PP): Offers excellent moisture resistance and is suitable for inner lining and pouches.

Polyethylene (PE): Used for bags and liners, providing a good seal.

Metallized films: Offer superior barrier properties, protecting against light and oxygen, extending shelf life.

Cardboard boxes: Used for outer packaging, providing structural support during transportation.

The packaging design should consider the following:

Size and weight: Optimize the package size and weight for efficient loading and shipping, minimizing transportation costs.

Sealing: Ensure airtight and tamper-evident sealing to prevent contamination and maintain freshness.

Cushioning: Utilize cushioning materials like bubble wrap or foam to protect the dried mango slices from impact during handling.

Vacuum Packing: For certain grades of dried mangoes, this is essential to remove all oxygen and prevent from deterioration.

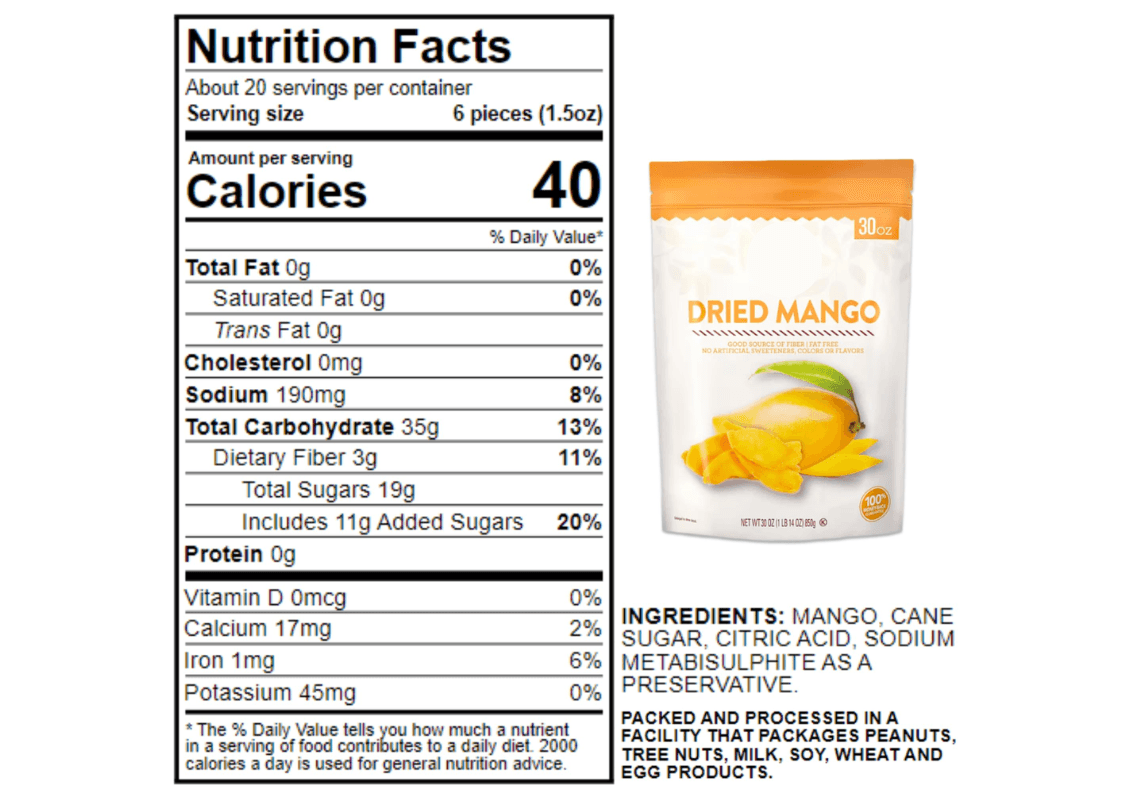

Clear and accurate labeling is essential for compliance with international regulations and to provide consumers with necessary information. Labels should include:

Product name: “Dried Mango”

Ingredients list

Net weight

Manufacturing and expiry dates

Country of origin: Dried Mango Vietnam.

Manufacturer's name and address

Storage instructions

Nutritional information (as required by the destination market)

Allergen information (if applicable)

Preservation Techniques

To further extend the shelf life and maintain the quality of dried mango costco, consider the following preservation techniques:

Modified Atmosphere Packaging (MAP): Involves altering the gas composition inside the package to slow down spoilage.

Vacuum packaging: Removes air from the package, inhibiting oxidation and microbial growth.

Desiccants: Place silica gel sachets in the packaging to absorb moisture and prevent softening or mold growth. All dessicants should be food grade. The packaging should be air tight.

Complying with International Standards

When exporting cebu dried mango, it's crucial to adhere to the packaging standards and regulations of the importing country. Some relevant standards include:

Food Safety Regulations: These regulations dictate the materials allowed for food contact and the labeling requirements.

Packaging Waste Regulations: Some countries have regulations regarding packaging waste reduction and recyclability.

Phytosanitary Certificates: These certificates certify that the dried mango is free from pests and diseases.

Effective export packaging specifications are vital for ensuring the quality, safety, and marketability of dried mango. By carefully selecting packaging materials, implementing appropriate preservation techniques, and adhering to international standards, exporters can protect their product, build trust with buyers, and expand their global reach. Contact us today to learn more about food-grade, internationally compliant packaging solutions for your dried fruit exports.

Q: What are the most common problems with dried mango packaging?

A: The most common problems include moisture absorption leading to softening and mold, damage during transit due to insufficient cushioning, and non-compliant labeling leading to customs issues.

Q: What type of packaging provides the best protection against moisture?

A: Metallized films and polypropylene (PP) are excellent choices for providing a strong moisture barrier.

Q: What information is required on the label of dried mango packaging for export?

A: Essential labeling requirements include the product name, ingredients, net weight, manufacturing and expiry dates, country of origin, and manufacturer's details.

Q: Is vacuum packaging necessary for all types of dried mango?

A: While not always necessary, vacuum packaging is highly recommended for extending shelf life and preventing oxidation, particularly for premium-quality dried mango.

Q: What are some best practices for packing dried mango into boxes for shipping?

A: Use sturdy cardboard boxes, ensure the inner packaging is sealed tightly, use cushioning materials to prevent movement, and properly label the boxes with handling instructions.

Q: How can I ensure my packaging materials are food-grade?

A: Request certifications from your packaging supplier confirming that the materials meet food-grade standards, such as FDA approval or equivalent international certifications.

May 22, 2025

Learn how to use AI to streamline international agricultural sourcing. Discover tools, strategies, and benefits for smarter, faster global procurement.

May 22, 2025

Discover how AI tools revolutionize agricultural sales and trading. Explore top AI assistants, chatbots, pipeline automation, and smart negotiation tools.

May 21, 2025

Discover the top 5 AI tools for automating sales pipelines in trading. Boost lead conversion, streamline deal flow, and improve forecasting with AI-powered sales systems.